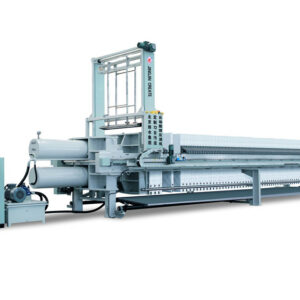

A hydraulic filter is a critical component of a hydraulic system that is used to remove contaminants from hydraulic fluid. The hydraulic filter is designed to keep the hydraulic fluid clean and free of debris, which can improve the performance and lifespan of the hydraulic system.

Here is a look at the processes, types, and applications of hydraulic filters:

Processes:

Hydraulic filters work by trapping and removing contaminants from the hydraulic fluid as it flows through the filter. The filter media may be made of materials such as cellulose, synthetic fibers, or metal mesh, which are designed to capture different types and sizes of contaminants. The hydraulic filter may also include a bypass valve that allows the hydraulic fluid to bypass the filter if the filter becomes clogged or overloaded.

Types:

There are several types of hydraulic filters, including:

In-line filters: These filters are installed in the hydraulic line and can be easily replaced or serviced.

Spin-on filters: These filters are designed to be screwed onto a filter head and can be quickly replaced without the need for tools.

Suction filters: These filters are installed in the hydraulic reservoir and are designed to prevent debris from entering the hydraulic pump.

Return line filters: These filters are installed in the return line of the hydraulic system and are designed to remove contaminants from the hydraulic fluid as it returns to the reservoir.

Applications:

Hydraulic filters are used in a wide range of applications, including:

Construction equipment: Hydraulic filters are used in construction equipment, such as excavators, bulldozers, and loaders, to improve the performance and lifespan of the hydraulic system.

Agriculture equipment: Hydraulic filters are used in agriculture equipment, such as tractors and combines, to keep the hydraulic fluid clean and free of debris.

Industrial machinery: Hydraulic filters are used in industrial machinery, such as presses, mills, and injection molding machines, to ensure the proper function of the hydraulic system.

Automotive: Hydraulic filters are used in automotive applications, such as power steering systems and automatic transmissions, to keep the hydraulic fluid clean and free of debris.

Overall, hydraulic filters are a critical component of hydraulic systems that help to improve their performance and lifespan. By choosing the right type of hydraulic filter and maintaining it properly, you can ensure the proper function of your hydraulic system and prevent costly repairs and downtime.

6 Simple Tips to Prepare Your China filter hydraulic factories

Preparing your China filter hydraulic factories for efficient and effective production can help you save time and money.

Here are six simple tips to help you prepare your factories:

Organize the workspace: Clear the workspace of any unnecessary clutter, and organize tools and equipment to maximize workflow. This will help you save time and reduce the risk of accidents or injuries.

Ensure proper lighting: Ensure that the workspace is properly lit, and replace any burnt-out light bulbs. China filter hydraulic factories Good lighting will help you see what you’re doing and improve productivity.

Clean the machines: Clean the machines and equipment thoroughly to remove any debris or contaminants that may affect the quality of the filters. This will improve the efficiency of the machines and ensure that your filters meet quality standards.

Stock up on supplies: Ensure that you have all the necessary supplies, such as filter media, filter housings, and other components, to avoid delays in production.

Train and educate employees: Train and educate employees on the proper use of machines and equipment, as well as safety guidelines. This will help reduce the risk of accidents and improve productivity.

Develop a production schedule: Develop a production schedule that allows you to efficiently produce the required number of filters without overloading the machines or employees. This will help you avoid delays and ensure that you meet customer demand.

Overall, preparing your China filter hydraulic factories for production requires careful planning and attention to detail. By following these simple tips, you can improve the efficiency and effectiveness of your production process, and ensure that your filters meet quality standards.