Concrete is one of the most widely used construction materials due to its strength and durability. However, it is prone to cracking and other forms of damage over time, especially under heavy loads or exposure to harsh environmental conditions.

What is Glued Steel Fiber in Concrete?

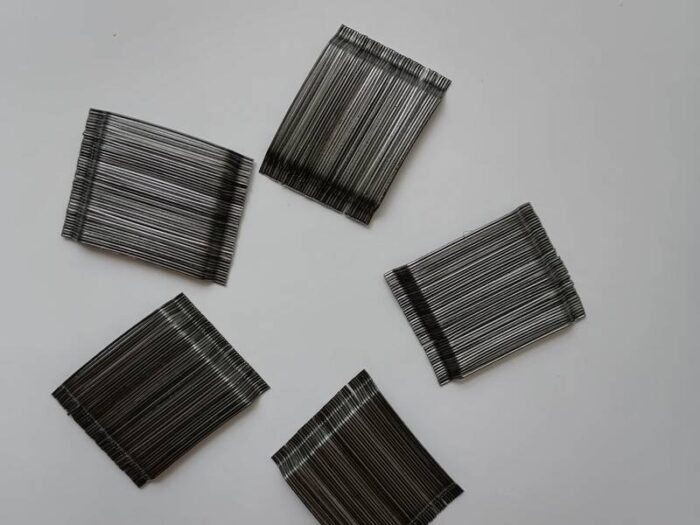

Glued steel fiber in concrete is a type of reinforcing material that is added to concrete to improve its strength, durability, and resistance to cracking. The fibers are made of high-strength steel wire or bars that are coated with an adhesive material to bond them to the concrete. Once added to the concrete mix, the fibers distribute evenly throughout the material, providing enhanced reinforcement and preventing the formation of cracks.

Benefits of Using Glued Steel Fiber in Concrete

The addition of glued steel fiber in concrete offers several benefits, including:

- Increased Durability: The fibers enhance the tensile strength of the concrete, making it more resistant to cracking and other forms of damage.

- Improved Flexural Strength: The fibers also improve the concrete’s flexural strength, allowing it to withstand heavy loads and stresses.

- Reduced Shrinkage: The fibers help to control the shrinkage of the concrete, reducing the risk of cracking and other forms of damage.

- Enhanced Fire Resistance: The steel fibers can improve the fire resistance of the concrete, making it a safer and more reliable building material.

Types of Glued Steel Fiber

There are several types of glued steel fiber available for use in concrete, including:

- Hooked End Fibers: These fibers have a hooked end design that provides a stronger bond with the concrete and enhances their ability to distribute stress.

- Straight Fibers: Straight fibers are the most commonly used type of steel fiber in concrete. They are cost-effective and provide good reinforcement.

- Crimped Fibers: Crimped fibers have a zigzag shape that improves their bond with the concrete and enhances their ability to distribute stress.

- Waved Fibers: Waved fibers are similar to crimped fibers but have a more pronounced wave pattern that enhances their ability to distribute stress.

Best Practices for Using Glued Steel Fiber in Concrete

To ensure the best results when using glued steel fiber in concrete, it is important to follow these best practices:

- Choose the Right Type of Fiber: The type of fiber used should be chosen based on the specific needs of the project, including the desired strength and durability.

- Use the Right Amount of Fiber: The amount of fiber used should be carefully calculated to ensure optimal reinforcement without negatively affecting the workability of the concrete.

- Mix the Fiber Thoroughly: The fibers should be mixed thoroughly into the concrete to ensure even distribution throughout the material.

- Use the Right Equipment: The use of specialized equipment, such as fiber dispensers, can help to ensure accurate and efficient mixing of the fibers.

- Follow Proper Installation Procedures: The installation of concrete reinforced with glued steel fiber should follow standard procedures, including proper curing and finishing.

Conclusion

Glued steel fiber in concrete is an effective solution for enhancing the durability and strength of concrete. With the ability to control cracking, withstand heavy loads, reduce shrinkage, and improve fire resistance, it is a valuable addition to any construction project. By following best practices for its use, including choosing the right type and amount of fiber, thoroughly mixing it into the concrete, and following proper installation procedures, builders can ensure optimal results and long-lasting performance.