15-degree ring shank coil nails, when used with pneumatic nail guns, are generally much faster than traditional hand-driven nails.

Here’s how they compare in terms of speed:

- Pneumatic application: 15-degree ring shank coil nails are designed to be used with pneumatic nail guns, which automate the nailing process. With a nail gun, a single pull of the trigger can drive multiple nails rapidly, significantly speeding up the installation process compared to hand-driving nails individually.

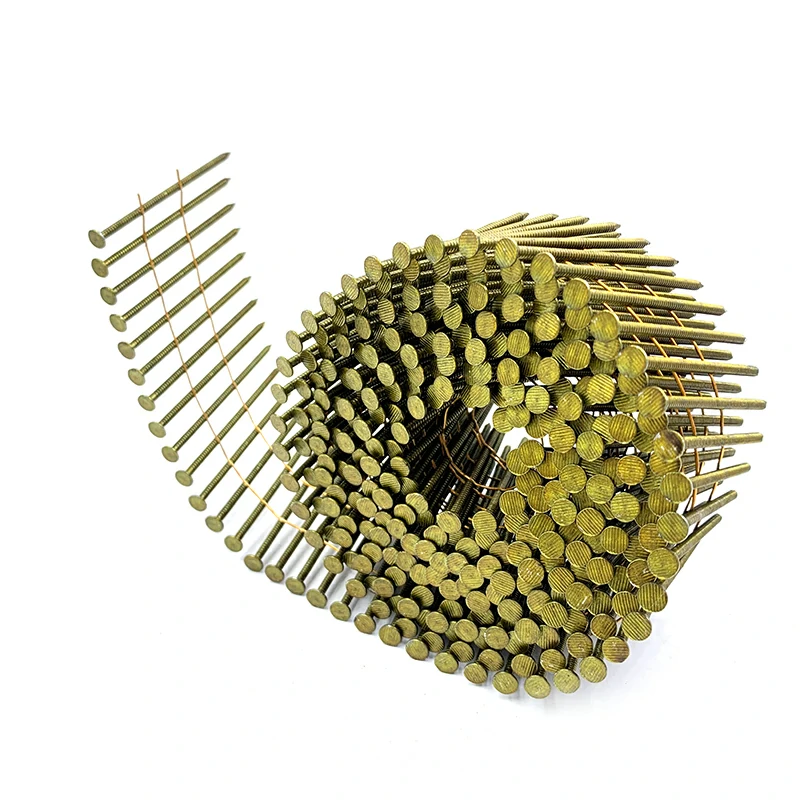

- Continuous feed: Coil nails come wound in coils, allowing for continuous feeding into the nail gun without the need to reload after each nail. This continuous feed feature eliminates the downtime associated with reloading nails, further increasing the speed of installation.

- Efficient nailing: Ring shank coil nails, with their textured shank that provides enhanced holding power, can be driven quickly and securely into the substrate with pneumatic nail guns. 15 degree ring shank coil nails This efficiency allows for rapid nailing without compromising on the strength and stability of the fastening.

- Reduced fatigue: Using a pneumatic nail gun with 15-degree ring shank coil nails can significantly reduce the physical strain and fatigue experienced by workers compared to hand-driving nails. This reduction in fatigue allows workers to maintain a consistent pace and productivity level over extended periods.

- Greater coverage: With their rapid firing capability, pneumatic nail guns equipped with 15-degree ring shank coil nails can cover a larger area in a shorter amount of time compared to hand-driving nails. This makes them particularly well-suited for large-scale construction projects where speed and efficiency are essential.

In summary, 15-degree ring shank coil nails used with pneumatic nail guns offer a considerable speed advantage over traditional hand-driven nails. The combination of pneumatic application, continuous feed, efficient nailing, reduced fatigue, and greater coverage allows for significantly faster installation times, making them a preferred choice for many construction professionals seeking to maximize productivity and efficiency on the job site.