Discover the versatility and advantages of using a 90 degree coupler in various applications. This article explores the benefits and applications of the 90 degree coupler, including its ability to provide efficient and reliable connections in tight spaces.

Learn how the 90 degree coupler enhances productivity, saves time and cost, and ensures seamless installations. Explore key considerations when selecting a 90 degree coupler, such as material compatibility, load capacity, and installation requirements. Unlock the potential of your projects with the efficiency and flexibility of the 90 degree coupler.

Introduction: Enhancing Connectivity with the 90 Degree Coupler

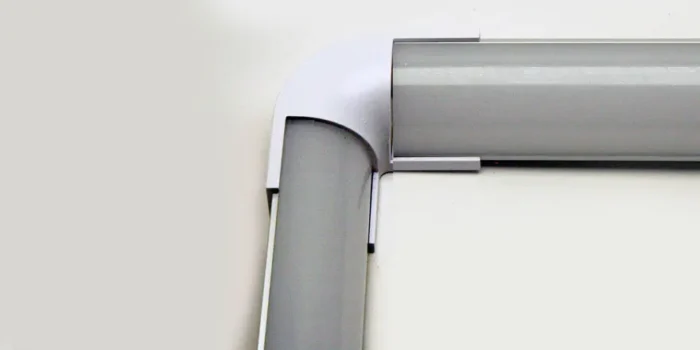

The 90 degree coupler is a versatile component that enhances connectivity by providing efficient and reliable connections in tight spaces.

Benefits of the 90 Degree Coupler

- Space Optimization: The 90 degree coupler allows for connections at right angles, optimizing space utilization and enabling installations in confined areas.

- Efficient Installations: With its user-friendly design, the 90 degree coupler simplifies installation processes, saving time and reducing labor costs.

- Flexibility and Versatility: The 90 degree coupler accommodates various materials and applications, providing flexibility in design and adapting to project requirements.

- Reliable Connections: The 90 degree coupler ensures strong and secure connections, enhancing the structural integrity and longevity of the connected components.

Applications of the 90 Degree Coupler

- Plumbing and HVAC Systems: The 90 degree coupler is commonly used in plumbing and HVAC systems to connect pipes and fittings at right angles, enabling efficient routing in tight spaces.

- Electrical Installations: In electrical installations, the 90 degree coupler facilitates the connection of conduits and fittings, allowing for neat and organized wiring layouts.

- Furniture Assembly: The 90 degree coupler is employed in furniture assembly, enabling the construction of modular furniture and providing stability and strength to the overall structure.

Key Considerations When Selecting a 90 Degree Coupler

- Material Compatibility: Choose a 90 degree coupler that is compatible with the materials being connected, ensuring a secure and durable connection.

- Load Capacity: Consider the load requirements of the application to select a 90 degree coupler with the appropriate load capacity.

- Installation Requirements: Evaluate the installation process and requirements to choose a 90 degree coupler that offers ease of installation and compatibility with the available tools and equipment.

Example of 90 Degree Coupler Application

In a plumbing project, the 90 degree coupler is used to connect pipes at right angles in a tight corner. The compact design of the coupler allows for efficient utilization of space, enabling the plumbing system to be installed seamlessly. The secure connection provided by the 90 degree coupler ensures reliable water flow and minimizes the risk of leaks or pipe failure.

Conclusion: Unlock Efficiency and Flexibility with the 90 Degree Coupler

The 90 degree coupler offers a range of benefits, including space optimization, efficient installations, flexibility, and reliable connections. By selecting the appropriate 90 degree coupler and considering key factors such as material compatibility and load capacity, you can maximize efficiency, save time and cost, and ensure seamless installations in various applications.

In summary, the 90 degree coupler is a versatile component that enhances connectivity in tight spaces. Whether in plumbing, electrical installations, or furniture assembly, the 90 degree coupler provides efficient and reliable connections, optimizing space utilization and enhancing structural integrity.